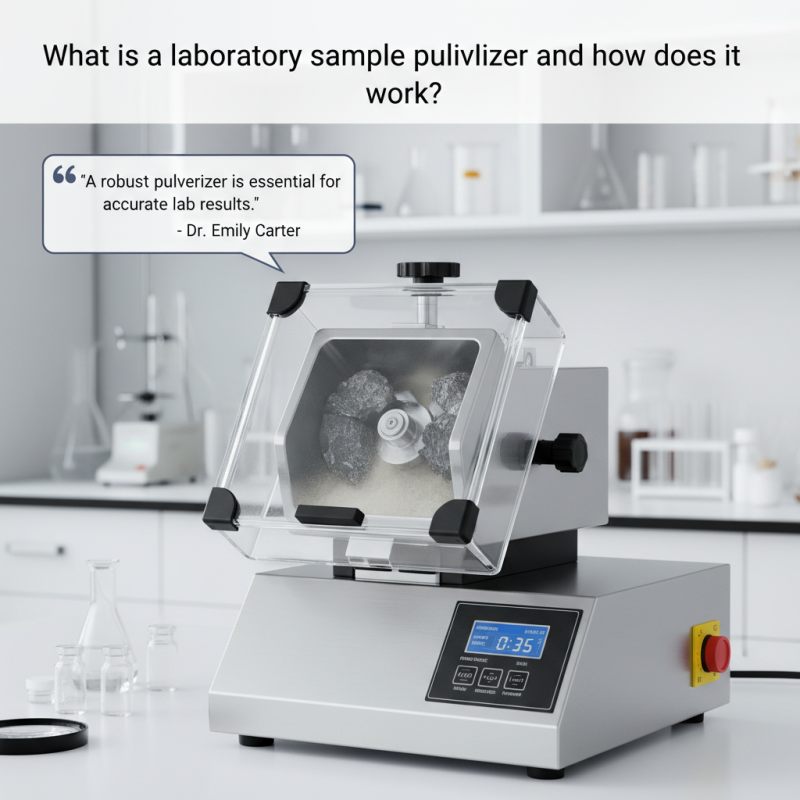

In the realm of materials testing, the laboratory sample pulverizer plays a crucial role. Dr. Emily Carter, a leading expert in sample preparation, states, “A robust pulverizer is essential for accurate lab results.” This machinery efficiently reduces samples to fine powders, facilitating various analytical processes.

Typically utilized in geology and material science, laboratory sample pulverizers aid in obtaining homogenous samples. With robust blades and precise settings, they ensure consistency in particle size. However, selecting the right pulverizer can be challenging. Factors like desired grain size and sample type must be considered.

Proper maintenance of laboratory sample pulverizers often goes overlooked. Neglecting this can lead to inconsistent results and increased operational costs. Awareness and training are key to maximizing their potential. With the right attention, these devices not only enhance productivity but also ensure reliability in scientific findings.

A laboratory sample pulverizer is a vital tool in many research and industrial settings. It is designed to grind and crush materials into fine powders. This process is essential for accurate analysis and testing. When samples are reduced to a uniform particle size, the results become more reliable.

Typically, a pulverizer consists of grinding plates and a hopper. The sample is placed in the hopper for processing. As the machine operates, the grinding plates crush the materials. The speed and pressure can be adjusted for different materials. Some users may find the setup complicated or not intuitive. Proper maintenance is crucial, as wear and tear affect performance.

Different types of samples require varied pulverization techniques. For instance, some materials may be brittle, while others are tough. Experimenting with parameters can yield better results, but it often requires time and patience. Users frequently have to recalibrate settings to achieve optimal performance. This trial-and-error aspect is essential for perfecting the process.

A laboratory sample pulverizer is essential for material processing. It reduces samples to a fine powder, crucial for various analyses. The key components of a pulverizer include the grinding chamber, grinding plates, and motor. Each component plays a role in delivering precise results.

The grinding chamber houses the sample. It is built to withstand high forces. Grinding plates are the heart of the machine. They crush and grind the material. The motor drives the grinding plates, providing the necessary power. Adjustments can be made to control the fineness of the grind.

Tips: Regular maintenance is vital. Check the grinding plates for wear. If they show signs of damage, replace them. Also, cleaning the chamber prevents cross-contamination. Different materials can cling to surfaces, affecting future samples.

Different sample types may require specific settings. Adjust the speed based on the material's hardness. Too fast can overheat the sample. Too slow may not achieve the desired fineness. Experimenting with these adjustments can enhance result accuracy. Remember, not all pulverizers are equal. Testing various settings can lead to better outcomes.

Laboratory sample pulverizers are essential tools in material analysis. They play a critical role in preparing samples for tests. The core operation is quite mechanical yet effective. These devices crush materials into fine particles. The goal is to ensure uniformity in the sample size. This uniformity is vital for accurate testing results.

Mechanical operation relies on high-impact forces. Many pulverizers utilize rotating blades or hammers to achieve this. They can reach speeds up to several thousand RPM. Some models can process a few grams to several kilograms of material at once. According to industry reports, precise particle size distribution is crucial in fields like mining and pharmaceuticals. In these industries, a variation as small as 5% can lead to significant discrepancies in results.

However, the design and operation of these machines can lead to challenges. For instance, material build-up can occur in the chamber over time. This can affect sample integrity if not properly monitored. Regular maintenance and calibration are needed, but sometimes overlooked. Ensuring accuracy means investing time into proper equipment care and operator training. Unchecked, these issues can compromise the entire testing process. Inadequate attention to detail can cause delays and inaccuracies.

Laboratory sample pulverizers play a crucial role in research and testing. These machines reduce solid materials into fine powders for analysis. They are essential in various fields, including geology, pharmaceuticals, and material science. Researchers often rely on pulverizers to obtain uniform samples. This consistency is vital for accurate test results.

In geology, for instance, pulverizers help analyze soil and rock samples. By grinding the material to a fine texture, scientists can perform better chemical analyses. They need precise data to understand mineral compositions. In pharmaceuticals, sample pulverizers aid in the formulation of drugs. A fine powder ensures that active ingredients mix evenly.

Despite their importance, sample pulverizers can be challenging to master. Researchers sometimes struggle to find the right settings. The balance between speed and fineness is delicate. Over-pulverizing can lead to unwanted heat generation, altering the sample properties. Adjusting settings requires experience and careful observation. This need for expertise calls for further training and workshops. Understanding how to use these machines effectively is essential for any research team.

| Feature | Description |

|---|---|

| Function | Reduces large materials to a fine powder for analysis. |

| Applications | Used in materials science, geology, and metallurgy. |

| Types of Pulverizers | Jaw crushers, ball mills, and disk pulverizers. |

| Operational Principle | Materials are crushed and ground using mechanical force. |

| Importance | Facilitates accurate and reproducible analysis in research. |

| Sample Size | Can handle various sample sizes, from milligrams to grams. |

| Safety Features | Often includes dust extraction systems and emergency shut-off. |

Laboratory sample pulverizers play a crucial role in material analysis across various industries. They are designed to crush and grind samples to a fine powder. This process is essential for preparing specimens for further examination. The pulverization process can effectively reduce samples like ores, minerals, and chemicals to the desired particle size.

Common materials processed by these pulverizers include rocks, coal, and soil samples. According to industry data, more than 60% of laboratories utilize pulverizers for geological materials. For example, pulverized rock samples are crucial in geochemistry. They help in determining mineral content and structure. Soil samples undergo this process to assess agricultural viability. This ensures proper nutrient management and crop yield forecasting.

The versatility of laboratory sample pulverizers extends to industrial applications as well. Materials like plastics and ceramics are processed for quality control. Yet, not all samples are easy to pulverize. Certain materials may resist grinding, leading to variable results. This inconsistency in sample preparation can impact analytical outcomes. Continuous improvement in pulverization techniques is essential to overcome these challenges. The industry must invest in research to enhance efficiency and precision in sample processing.